Manufacturing Process

[1] RAW MATERIALS

The first step is to weigh

[2] MIXING

Dry mix and ball mill the raw materials

[3] Calcining

The uniform mixture is then heat treated (calcined) during which the components react to form the polycrystalline phase

[4] MILLING

[5] SPRAY DRYING

The calcined powder is spray dried to add binder in order to increase it's reactivity and to improve pressing properties.

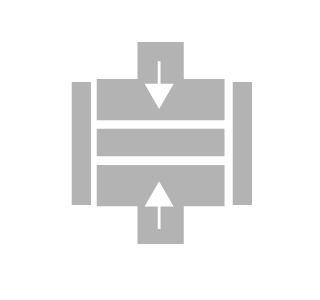

[6] PRESSING

Shaping by dry-pressing

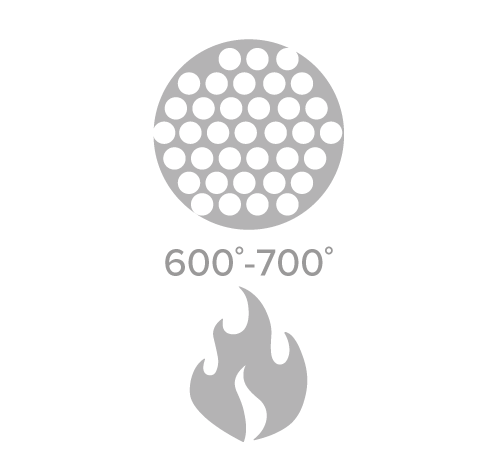

[7] BINDER BURNOUT

The binder is burnt out by slowly heating the green ceramics to around 700oC

[8] SINTERING

The parts are transferred to another furnace, where they are sintered between 1200oC and 1300oC

[9] GRINDING / POLISHING

The dimensional tolerance of fired parts is improved by cutting, grinding, lapping etc.

[10] ELECTRODING

Electrodes are applied either by screen printing, chemical plating or vacuum deposition

[11] POLING

Poling then is carried out by heating in an oil bath above Curie Temperature, and applying an electrical field of 2-8 kV/mm to align the domains in the material.

[12] FINAL INSPECTION

Final inspection is performed after a minimum of 24 hours later, and includes testing of electrode-ceramic bonding as well as measurement of dimensional tolerances, dielectric and piezoelectric properties.