Definitions & Terminology

Definitions & Equations

Dielectric Constant

The relative dielectric constant is defined as the ratio of the permittivity of the material to the permittivity of free space. This generally measured well below the mechanical resonance. The dielectric constant is derived from the static capacitance measurements at 1kHz using a standard impedance bridge.

![]()

Dielectric Loss Factor

The dielectric loss factor is defined as the tangent of the loss angle (tan δ). The loss factor represents the ratio of resistance to reactance of a parallel equivalent circuit of the ceramic element. The loss factor cam be measured directly using an impedance bridge.

Mechanical QM Factor

The mechanical QM factor is the ratio of the reactance to the resistance in the series equivalent circuit representing the piezoelectric resonator. The QM factor is also related to the sharpness of the resonance frequency.

![]()

Alternatively the QM factor can also be determined using the equation:

![]()

Frequency constants

The frequency constant, N, is the product of the resonance frequency and the linear dimension governing the resonance. The various modes of resonance are shown schematically in the Modes of Vibration section.

N1 = frL Transverse mode, thin bar

Np = frD Radial mode, disc

Nt = frT Thickness mode, disc

N3 = frL Length mode, cylinder

Ns = frT Shear mode, plate

Piezoelectric Coupling Coefficient

The coupling coefficient (electromechanical coupling coefficient) is defined as the ratio of the mechanical energy accumulated in response to an electrical input or vice versa.

![]()

![]()

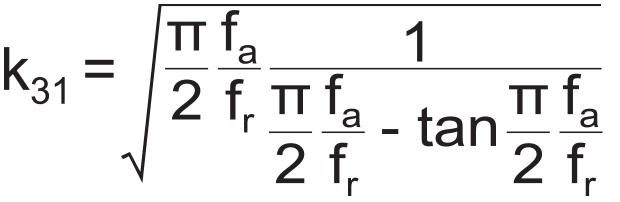

The coupling coefficient can be calculated for the various modes of vibration:

![]()

![]()

k33 and k15 can be calculated similar to kt by using the appropriate resonance frequencies.

Another parameter, keff, is frequently used to express the effective coupling coefficient of an arbitrary resonator, either at fundamental resonance or at any overtone and is expressed as follows:

![]()

Piezoelectric Charge Coefficients

The piezoelectric charge coefficient is the ratio of electric charge generated per unit area to an applied force (C/N).

![]()

The d constants are calculated from the equation:

![]()

![]()

![]()

![]()

Piezoelectric Voltage Coefficient

The piezoelectric voltage coefficient is the ratio of the electric field produced to the mechanical stress applied (Vm/N).

![]()

![]()

The g constants are calculated from the equation:

![]()

![]()

![]()

![]()

Elastic Compliances

Young’s modulus describes the mechanical stiffness properties and is expressed as the ratio of stress to strain. In a piezoelectric material, mechanical stress produces an electrical response, which opposes the resultant strain. The value of the Young’s modulus depends on the direction of the stress and strain and the electrical conditions. The inverse of Young’s modulus, Y, is the elastic compliance, s.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Aging Rate

The aging rate of a piezoelectric ceramic is an index of the change of certain material parameters with time:

![]()

T1, t2 are number of days after polarization

P1, P2 are measured parameter.